• Internal load-bearing structure in hot-dip galvanized steel profile Z140. construction compatible with EN1886, mechanical resistance class D1.

• External casing in sandwich panel, 25 mm thick, made of 6/10 thick steel sheet. Inner sheets hot-dip galvanized Z140, outer prepainted sheets RAL 9010 coated with protective PVC film. Internal insulation using high density (40 kg/m3) expanded polyurethane.

• Airtightness guaranteed by a highly adaptable and elastic neoprene flange.

• Opening panels, clamped with push bolts that ensure sufficient and stable pressure on the sealing gaskets.

• Condensate collection tray made of AISI 304 stainless steel (EURONORM 1.4301), internally inclined to facilitate drainage, corresponding to areas subject to condensation.

• Aluminium counterflow heat exchanger, whose performance, with Eurovent certification, exceeds the requirements set by the Ecodesign Regulation N° 1253/2014/EU.

• Automatically controlled bypass damper (100% of air flow) to achieve the free cooling and free heating functions required by the Ecodesign regulation.

• 1 ePM10 60% (M5) filter at extraction and 1 ePM1 55% (F7) filter at delivery, both mounted on gasketed guides for effective sealing and mounted upstream of internal components to ensure adequate protection.

Exhaust ePM1 55% (F7), delivery ePM1 80% (F9), exhaust ISO Coarse 45% (G4) and exhaust ISO Coarse 40% (G2) filters, available as accessories.

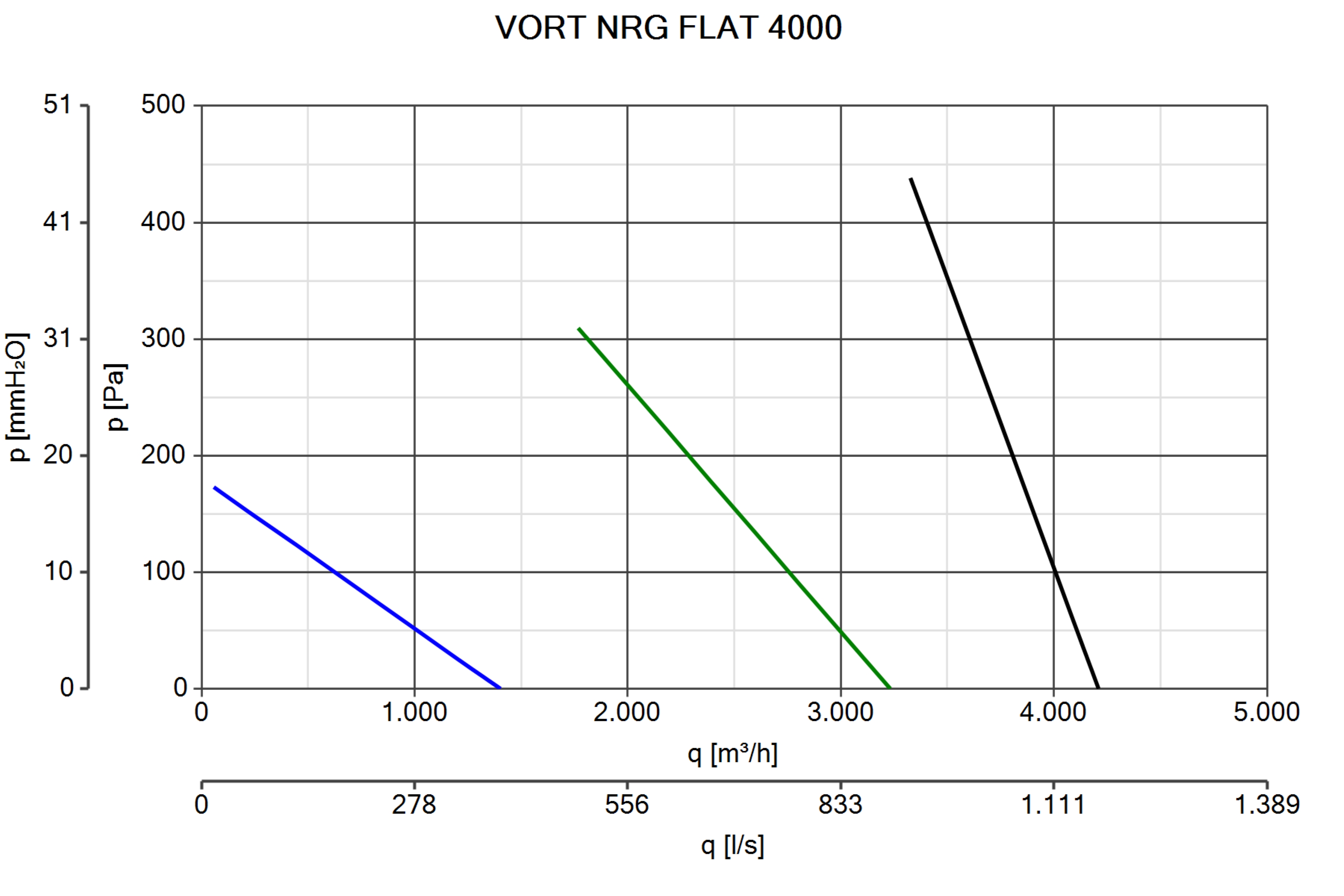

• Independently controlled fans, made of centrifugal blades made of galvanized steel, front blade type with aerodynamic profile, statically and dynamically balanced, directly connected to electronic motors (EC brushless), thermally protected and adjustable via 0-10V modulating signal.

• Electronic suite, including temperature sensors in the external air intake and ambient air intake, which monitors the operation of the machine. The user interface consists of a remote control panel with an LCD display. The installed microcontroller allows independent adjustment of the speeds of the two fans, automatic opening/closing of the motorized bypass damper mounted in correspondence with the heat exchanger, seasonal summer/winter change, the programming of the operation by time zones as well as, through a pair of differential pressure switches fitted as standard, the continuous monitoring of the condition of the filters and the activation of any alarm signal in case of failure to maintain them.

• Ability to manage a hot or cold water after-treatment coil (optional), controlled by a 3-way modulating valve (optional), managed by a room air intake sensor.

• Possibility of integration into the most modern home automation systems via RS485 serial port, provided as standard, Modbus communication protocol.

TEXNICA DATA AND PERFORMANCE DATA

- Refresh air filter category F7

- Exhaust air filter category M5

- Frequency (Hz)50

- Number of Phases (Ph)3

- Weight kg)393

- Maximum absorbed power (W)2060

- Rated power (W)1840

- Voltage (V)400

- Maximum flow rate (m³/h)3980

- Maximum flow rate (m³/h)3980[dB(A)]

- Sound Pressure Lp 1m67.3 [dB (A)]

DIMENSIONS

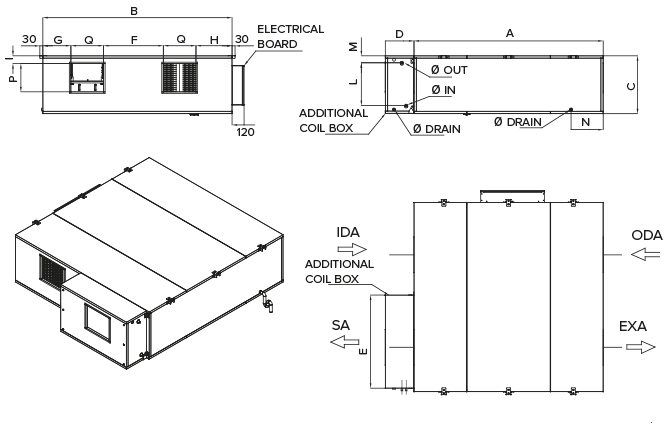

- Size A (mm)1900

- Size B (mm)1900

- Size C (mm)580

- Size D (mm)288

- Size E (mm)935

- Size F (mm)600

- Size G (mm)282

- Size H (mm)362

- Size I (mm)78

- Size L (mm)430

- Size M (mm)70

- Size N (mm)323

- PXQ = (mm)282 Χ 328

CAMPUS